The Future of Manufacturing is Circular: How Salesforce and IoT are Leading the Charge

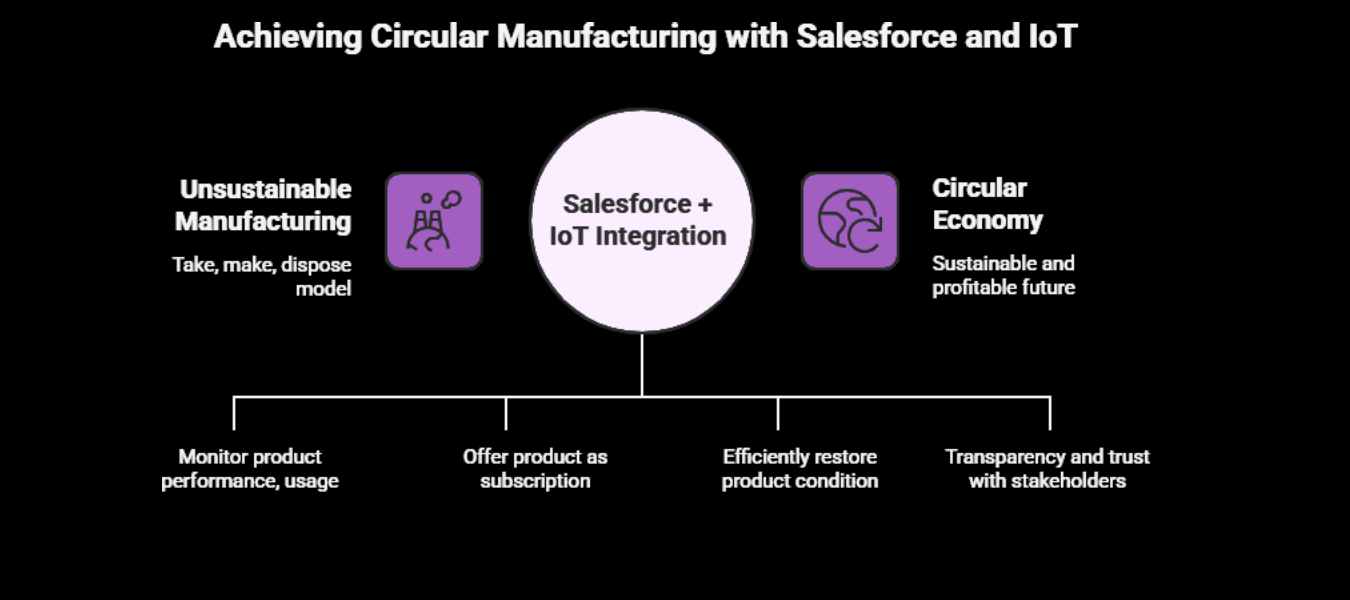

The global manufacturing landscape is undergoing a seismic shift. The traditional “take, make, dispose” model is proving unsustainable, giving way to a more resilient and responsible paradigm: the circular economy. For forward-thinking manufacturing leaders, this transition isn’t just an ethical imperative; it’s a strategic business opportunity. By embracing sustainability, manufacturers can unlock new revenue streams, enhance operational efficiency, and build a powerful brand that resonates with today’s conscious consumers and investors. At the heart of this transformation lies a powerful synergy: the integration of Salesforce Manufacturing Cloud with the Internet of Things (IoT).

The circular economy, in its essence, is about designing out waste and pollution, keeping products and materials in use for as long as possible, and regenerating natural systems. This represents a fundamental rethinking of how products are designed, produced, sold, and managed at the end of their life. For C-suite executives, the implications are profound, touching every aspect of the business, from supply chain and production to sales and customer service.

The challenge, however, has always been a lack of visibility. How can you manage a product’s entire lifecycle if you lose track of it the moment it leaves the factory? This is where the game-changing combination of Salesforce Manufacturing Cloud and IoT comes into play. By embedding IoT sensors into products, manufacturers can now gather real-time data on a product’s performance, health, and usage patterns. This continuous stream of data, when harnessed within the robust framework of Salesforce Manufacturing Cloud, provides the 360-degree view necessary to turn circular economy principles into a profitable reality.

From Product Sales to “Product-as-a-Service”: A New Revenue Frontier

One of the most exciting opportunities unlocked by this integration is the shift to a “Product-as-a-Service” (PaaS) model. Instead of a one-time sale, manufacturers can offer their products as a subscription service, with revenue tied to uptime, usage, or performance. Consider the example of an industrial air compressor manufacturer. Traditionally, they would sell the compressor and then separately sell maintenance contracts and spare parts.

With an IoT-enabled compressor feeding data into Salesforce Manufacturing Cloud, the manufacturer can now sell “compressed air as a service.” They are responsible for ensuring the compressor is always operational, using the real-time data to predict maintenance needs and proactively service the equipment before it fails. This model creates a predictable, recurring revenue stream for the manufacturer while providing the customer with a hassle-free, outcome-based solution. This deeper, ongoing relationship fosters immense customer loyalty and provides invaluable insights for future product development.

Closing the Loop: Remanufacturing and Recycling Made Easy

A core tenet of the circular economy is extending the life of products through remanufacturing, refurbishment, and recycling. The data captured through IoT is instrumental in achieving this. By understanding exactly how a product has been used, its current condition, and which components have experienced the most wear and tear, manufacturers can make intelligent decisions about its end-of-life pathway.

When a product is returned, the data within Salesforce Manufacturing Cloud can guide the remanufacturing process. Technicians can see the full service history, identify components that can be reused or refurbished, and efficiently restore the product to a like-new condition. This not only reduces the demand for virgin materials and the energy required for new production but also creates a new market for certified pre-owned products.

For products that have reached the end of their usable life, the same data can facilitate efficient recycling. By knowing the material composition of each component, manufacturers can streamline the disassembly and sorting process, ensuring that valuable materials are recovered and fed back into the production cycle, truly closing the loop.

Transparency and Trust: The Bedrock of ESG Reporting

In today’s investment landscape, robust Environmental, Social, and Governance (ESG) reporting is no longer a “nice-to-have”; it’s a critical component of corporate strategy.12 Investors and stakeholders are increasingly demanding transparency into a company’s sustainability practices.13 The integration of IoT data within the Salesforce ecosystem, particularly with Salesforce Net Zero Cloud, provides the granular, verifiable data needed for credible ESG reporting.

By tracking a product’s energy consumption throughout its lifecycle, monitoring waste reduction in the manufacturing process, and documenting the journey of recycled materials, companies can provide a detailed and accurate account of their environmental impact. This data-driven approach not only ensures compliance with evolving regulations but also builds trust with investors, customers, and employees. It transforms ESG reporting from a retrospective, compliance-focused exercise into a proactive, value-driving function of the business.

The Untapped Potential: A Call to Action for Manufacturing Leaders

The convergence of Salesforce Manufacturing Cloud and IoT represents a pivotal moment for the manufacturing industry. It offers a clear and actionable path toward a more sustainable and profitable future. The untapped potential lies in leveraging this powerful combination to not only optimise existing processes but to fundamentally reinvent business models and create new forms of value.

For C-suite executives, the time to act is now. The journey to a circular economy is a marathon, not a sprint, but the first step is to embrace the technologies that make it possible. By investing in the integration of Salesforce and IoT, manufacturing leaders can unlock a new era of innovation, drive long-term growth, and build a legacy of responsible and resilient manufacturing. The future of your business, and indeed the planet, may depend on it.