The concept of a “lights-out” factory, a fully autonomous manufacturing facility running with minimal or no human intervention, has transitioned from the realm of science fiction to a tangible, albeit challenging, reality. For C-suite executives, the allure of 24/7 productivity, unparalleled efficiency, and significant cost savings is a powerful motivator to explore this paradigm. But is today’s artificial intelligence truly capable of turning the lights out on traditional manufacturing for good?

The vision is compelling: a factory where intelligent robots and systems work tirelessly in the dark, churning out products with precision and speed that surpass human capabilities. This is not just about automation; it’s about autonomy. It’s a system that can sense, think, and act on its own, a prospect that promises to redefine the competitive landscape of modern industry.

The Engine of Autonomy: Core Technologies at Play

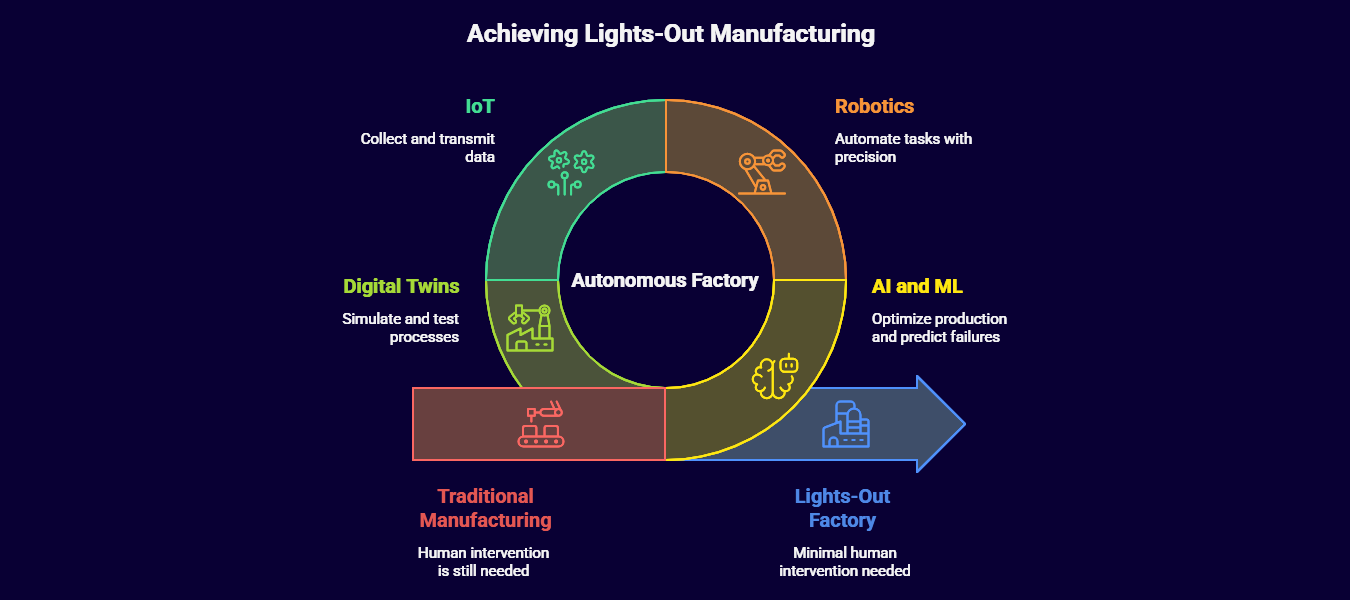

A fully autonomous factory is not the product of a single technology but rather the convergence of several key innovations. At the heart of this revolution is Artificial Intelligence (AI), the brain that powers the entire operation.

- AI and Machine Learning (ML): AI algorithms are the decision-makers. They optimize production schedules in real-time, predict equipment failures before they happen through predictive maintenance, and ensure flawless quality control by analyzing sensor data and visual feeds. ML models continuously learn and improve, making the manufacturing process smarter and more efficient over time.

- Robotics: Advanced robotics are the hands of the autonomous factory. These are not the single-task robots of the past but sophisticated machines capable of a wide range of tasks, from intricate assembly to heavy-duty material handling.

- Internet of Things (IoT): A vast network of interconnected sensors and devices forms the nervous system of the factory. These IoT devices collect and transmit massive amounts of data, providing the real-time information that AI needs to make informed decisions.

- Digital Twins: A virtual replica of the physical factory, the digital twin allows for simulation and testing of new processes in a risk-free environment. This technology is crucial for optimising workflows and planning for changes without disrupting actual production.

The Business Case: Why C-Suite Leaders are Paying Attention

The move towards a lights-out model is a strategic one, with a strong business case rooted in tangible benefits:

- Dramatically Reduced Labor Costs: While there is a significant upfront investment, the long-term savings on salaries, benefits, and the costs associated with human error can be substantial.

- 24/7 Productivity: Autonomous factories can operate around the clock, without breaks or holidays, leading to a massive increase in output and a faster return on investment.

- Enhanced Quality and Consistency: Automated systems can perform tasks with a level of precision and repeatability that is difficult for humans to match, resulting in higher quality products and less waste.

- Improved Workplace Safety: By automating dangerous and repetitive tasks, the risk of workplace accidents and injuries is significantly reduced.

The Reality Check: Hurdles on the Path to Full Autonomy

Despite the immense potential, the journey to a fully autonomous factory is fraught with challenges that every leader must consider:

- Exorbitant Initial Investment: The cost of outfitting a factory with the necessary robotics, sensors, and AI-powered software is substantial and can be a significant barrier for many organizations.

- Integration Complexity: Getting disparate systems—both new and legacy—to communicate and work together seamlessly is a major technical hurdle.14

- The Need for a New Kind of Workforce: While a lights-out factory eliminates many traditional manufacturing jobs, it creates a demand for highly skilled professionals who can design, implement, and maintain these complex autonomous systems.15

- Data Security: The vast amounts of data generated and utilized by an autonomous factory make it a prime target for cyberattacks.16 Robust cybersecurity measures are not an option; they are a necessity.

- Ethical Considerations: The societal impact of widespread automation and potential job displacement is a critical consideration that cannot be ignored.

Pioneers of the Dark Factory: Real-World Examples

While the fully autonomous, 100% lights-out factory remains a rarity, several companies have made significant strides in this direction:

- FANUC (Japan): A pioneer in this field, FANUC has been operating a “lights-out” factory for years to produce its own robots.17 In this facility, robots manufacture and assemble other robots, with minimal human oversight.

- Philips (Netherlands): The electronics giant utilizes a highly automated factory to produce electric razors.18 The facility operates with a small number of human employees who focus on quality control and system maintenance.

These examples demonstrate that while a completely human-free factory may not yet be the norm, the principles of lights-out manufacturing are being successfully applied to achieve significant operational benefits.

The Verdict: A Beacon for the Future, But Proceed with a Plan

So, is a fully autonomous factory possible with today’s AI? The answer is a qualified yes. The technology exists, and the potential rewards are immense. However, the path to a lights-out reality is a strategic journey, not a simple switch.

For C-suite leaders, the question is not just if but when and how to embrace this transformation. It requires a clear vision, a phased implementation strategy, and a significant investment in both technology and talent. The journey may be complex, but for those who navigate it successfully, the competitive advantage will be undeniable. The future of manufacturing is not just about making things; it’s about creating intelligent, self-sufficient systems that will power the industries of tomorrow. And in that future, the factories may very well be dark.